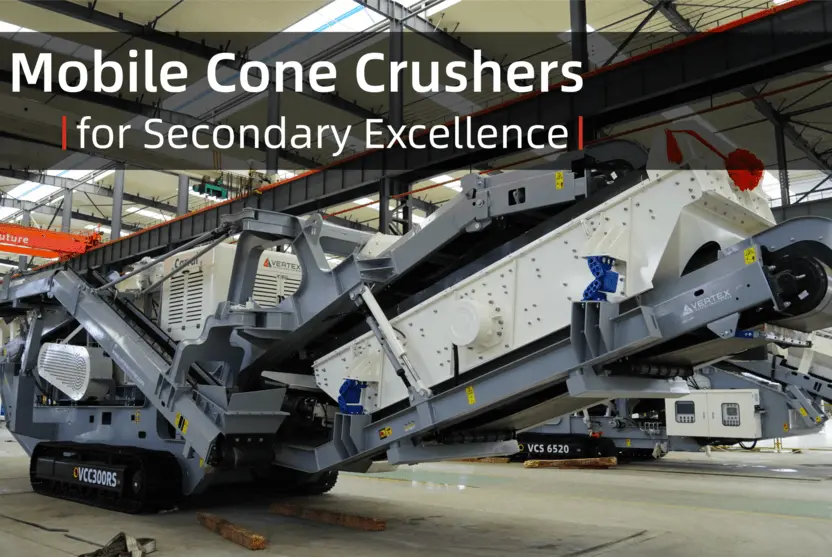

Definition and Value Proposition A mobile cone crusher is a type of crushing equipment that combines cone crushing technology with mobility. Unlike stationary crushers, these machines are mounted on tracks or wheels, allowing them to be easily relocated to different job sites. A cone crusher uses compression to crush materials between a moving cone (mantle) and a fixed cone (bowl liner), making it ideal for medium to hard materials.

In the broader aggregate crushing process, secondary crushing is the stage that follows primary crushing. While primary crushers like jaw crushers reduce large rocks into smaller chunks, secondary crushers refine those chunks into more uniform, high-quality aggregates ready for screening or tertiary crushing. Mobile cone crushers shine in this stage due to their precision, flexibility, and ability to produce cubical-shaped aggregates.

Secondary crushing plays a critical role in refining particle size and improving material shape. It ensures the material is suitable for construction applications, such as concrete and asphalt. At this stage, cone crushers are especially effective due to their consistent reduction ratio and ability to produce well-graded, angular aggregates.

Material Suitability:

Mobile cone crushers handle hard to medium-hard rocks efficiently.

Impact crushers are better for soft to medium materials, but wear out faster on hard materials.

Transport and Setup:

Transport and Setup:

Stationary cone crushers require concrete foundations and more installation time.

Maintenance and Operating Costs:

Mobile cone crushers offer lower maintenance intervals due to modular design.

Stationary units may require more downtime for component replacements.

Throughput and Performance:

While stationary systems can offer higher capacity, modern mobile cone crushers deliver competitive throughput for most secondary crushing needs.

Real-World Performance Considerations

In secondary crushing applications, mobile cone crushers offer an unmatched combination of precision, mobility, and efficiency. Their ability to adapt to varying site conditions while delivering high-quality aggregates makes them a smart investment for modern crushing operations. If you're optimizing your material processing workflow, a mobile cone crusher is likely the right tool for the job.