In the construction and mining industries, producing the right size and quality of aggregate is fundamental to project success. Whether you are building roads, bridges, or high-rise buildings, you need high-performance equipment to break down raw materials into usable forms. This is where aggregate crushers come in.

Aggregate crushers are powerful machines designed to reduce large rocks, stones, or recycled materials into smaller, specific sizes for use in concrete, asphalt, base layers, and other construction applications.

An aggregate crusher is a machine used to process large raw materials—such as stone, granite, limestone, gravel, or recycled concrete—into smaller pieces (aggregates) that are suitable for construction and industrial use. These machines are commonly found in quarries, mines, construction demolition sites, and aggregate production plants.

The primary function of an aggregate crusher is to:

Without aggregate crushers, turning natural stone or waste concrete into usable material would require significant labor and time

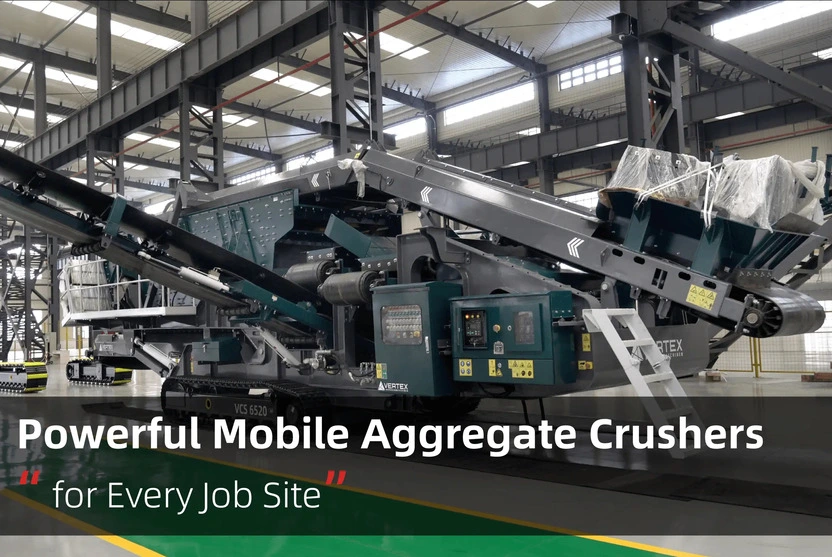

In today’s fast-paced construction and mining environments, mobile aggregate crushers have become the preferred choice due to their flexibility, compact design, and ability to operate directly on-site. At Vertex Crusher, we specialize in high-performance mobile crushing and screening solutions tailored for modern aggregate production.

Here are the most commonly used mobile aggregate crusher types:

What About Stationary Crushers?

While stationary crushers such as traditional jaw, cone, and impact crushers still play a role in large-scale, fixed-site

operations (like long-term mining projects), they require permanent foundations and are not ideal for rapidly changing

sites or urban construction zones.

To understand how aggregate crushers work, it’s helpful to break down their essential parts:

Advanced systems may also integrate automation, real-time diagnostics, and remote monitoring to enhance productivity and safety.

Aggregate crushers are indispensable in multiple industries and project types, including:

These machines help convert raw or waste materials into consistent, high-quality aggregates used in structural foundations, drainage, pavement, and backfill.

Benefits of Using Aggregate Crushers

Why are aggregate crushers essential? Because they deliver:

Modern crushers are also designed with energy efficiency and noise reduction in mind, supporting cleaner operations.

Selecting the right crusher depends on your application. Here’s what to consider:

Tip: It’s often beneficial to combine multiple types (e.g., jaw + cone + screening) in a production line for maximum efficiency.

Choosing and operating aggregate crushers—especially mobile ones—often comes with many questions. Below are some of the most common queries we receive from customers, along with expert answers to help you make informed decisions.

Q: Can aggregate crushers handle recycled materials like concrete or asphalt?

A: Absolutely. Mobile impact crushers and mobile jaw crushers are widely used for processing recycled materials such as concrete slabs, bricks, and old asphalt. They are equipped with reinforced structures and customizable discharge settings for optimal recycling performance.

Q: What’s the difference between a jaw crusher and a cone crusher?

A: A jaw crusher is best for primary crushing—breaking down large, hard materials into smaller chunks. A cone crusher, on the other hand, is designed for secondary or tertiary crushing and produces more finely shaped aggregates.

Q: How often should crushers be maintained?

A: Basic inspections should be performed every 100–200 operating hours, including checking wear parts, lubrication, and hydraulic systems. Full servicing, including replacement of key components, is recommended monthly or quarterly, depending on usage intensity.

Q: Are mobile aggregate crushers more expensive than stationary ones?

A: While mobile crushers may have a higher upfront investment, they often lead to significant cost savings in transport, setup time, and on-site efficiency. Over time, mobile units offer better ROI for projects requiring flexibility and fast deployment.

Q: Do I need additional equipment to run a mobile crusher?

A: Most mobile crushers come with integrated components like feeders, conveyors, and screening units. However, depending on your application, you might need additional mobile screening stations, stackers, or power sources (if operating off-grid).

Q: How do I choose the right type of aggregate crusher for my project?

A: Start by identifying:

The type and hardness of material,

Desired output size and shape,

Throughput capacity (tons per hour),

Site mobility requirements.

A mobile jaw crusher is great for large rocks and concrete, while a mobile cone crusher offers better shaping for high-spec aggregate.

Q: Can mobile crushers work in extreme environments or remote locations?

A: Yes. Many modern mobile crushers—like our crawler-mounted models—are designed to work in harsh terrains, tight urban zones, or isolated job sites without permanent infrastructure. They often feature dust suppression, noise control, and remote diagnostics.

Q: How long does it take to set up a mobile crusher on-site?

A: Most Vertex mobile crushers can be deployed and operational within a few hours. No concrete foundation is needed, making them perfect for time-sensitive projects and rapid site relocation.

Aggregate crushers are at the core of every efficient aggregate production system. From reducing large rocks to producing fine gravel, these machines transform raw materials into valuable construction components.

Choosing the right type and configuration of aggregate crusher can enhance your output quality, reduce costs, and improve overall plant productivity.